Any loose fill item needs baffles to hold that fill in place and give shape to the item. In most down garments on the market for 3-4 season use the baffles are created by sewing the inner and outer shells together. This separates the fill into separate chambers. However, at some point in time these sewn through baffle lines became fashionable. In my mind, I see it as that classic corporate tension between the engineering department and the marketing department, where the engineering department wants a warm for the weight garment and the marketing department wants to push fashion at a direct expense to performance. It seems that over the years, the marketing departments won out and the market is now dominated by jackets with tiny micro baffles, sometimes as narrow as 1″, all intersecting and skewing off at different angles.

The problem is that every one of those lines is a cold spot, with zero insulation. Furthermore, the narrower the chambers between the lines, the less that fill is able to loft up. So more cold spots and less insulation from the fill. It is true that as the total fill amount goes lower, you need narrower chambers to control it. You need narrower chambers and more lines to control light fill but can get away with wider chambers and fewer lines with heavier fill amounts. However, the industry today is most often putting out jackets with twice as many chambers as you would really need to control the fill amount….at least. Sometimes more.

Over the years I’ve done a bunch of testing on this. Swinging both towards narrower chambers/more control and to wider chambers/less control. Interestingly, even in my most extreme swings toward narrower, I’ve never come close to approaching the density of lines in most mass market jackets. Mostly because it’s soooo excessive, but also because each line has to be sewn. It’s labor intensive. Not only is it detrimental to performance, but it also costs more. I don’t know. These mass market jackets probably just go into a computerized machine that sews like 20 lines at once or something.

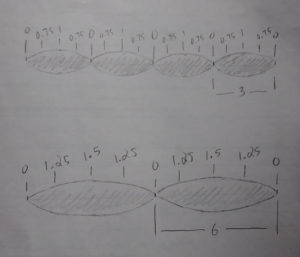

I have come to really prefer the widest spacing I can get away with. On multiple occasions, I have built essentially the same jacket back to back. Same calculations. Same fill amounts. Only one with 3″ spacing and the other with 6″ spacing. The difference in R-value is astounding. The level of control is more than adequate in the 6″ spaced jacket. No shifting or open spots at all.

This article was sick.

You’ve thought this out.

Thank you for explaining this. Great info!

Why not use a no sewn threw baffle system? The larger chambers arguements are great but it seems you seek the best possible engineering solutions and would at least offer interior baffles eliminating sewn threw seams period. I am very excited to have discovered your company and feel you are craftspeople with pride in your high quality products made in America.

The primary reason is that the calculated loft levels of the SUL and SDUL sweaters are lower than the threshold where there is enough room for a vertical baffle. It must be lower than the loft height by a certain amount to achieve the density needed. The 1.5s start to get near the threshold but the baffle would be so low that it’s worth becomes questionable. When we offer these sweaters in higher calculated lofts, then it might make sense. However, then there is a debate about it. We could box baffle an SUL 2, but we might double the price and add the weight of a baffle system or we could build a sewn through SUL 2.5 for the same warmth (increased fill offsets the baffle efficiency) for the same weight (trading the baffle weight for increased fill) for half the price. At some point baffles clearly make sense. For this in between zone, it is much more nuanced, not just from a cost standpoint, but also from a weight focused perspective.

Your information is great. Thanks for the “facts” assuming you are correct with your numbers. Thanks

Given that the Nunatak Skaha UL Down Sweater has a box baffle construction with average 1” loft, Would the SUL 1.5 be comparably warm even though the Skaha uses a fair amount more down (~5oz vs 3.8oz)? They give a static comfort rating of 20F with adequate layering.

It is impossible to use total fill weight as a comparison metric here. The Skaha’s total fill weight is spread over a garment with a hood, insulated pocket, zipper draft tube, different fit dimensions, and whatever else we can’t see. The SUL spreads its total fill weight over none of that and it is all in the body and sleeves. Fit dimensions and taper are likely different too. If you really want a fool-proof comparison you’ll need to ask for the chamber fill calculations. This info is right in the title of the SUL sweaters. 1.5 is the calculated loft. If a chamber is 10″ by 6″, that is multiplied by 1.5 and you find that there is 90 cubic inches of down fill in that space. Divide that by 900 fill power and you find that there is .1 ounces of fill in that space. If you know the quantity of down in any given portion, all those variables above no longer matter. The other metric you’d want to know is measured baffle height. For instance, say the Skaha uses 1.5″ calcualted loft and a .75″ baffle, it is likely a warmer garment than an SUL 1.5 that has 1.5″ calc loft and a 0″ baffle height. If the Skaha uses 1″ of calc loft and a .5″ baffle, then they might end up being pretty similar in overall warmth. The Skaha would have its insulation spread evenly. The SUL would have peaks of high loft, broken up by the sewn through spots with the average landing somewhere similar.

The take-away is that you need more information to compare warmth. If you were unable to obtain more info, then I would defer to measured loft, rather than total fill weight. Measured loft is not great either, but it is a bit more in the ballpark. An SUL 1.5 will have somewhere between 1.5″ – 2″ measured loft at mid-chamber, split by a sewn through spot every 6″.

Dan, thank you for these thoughtful, detailed, nuanced responses. This level of detail has been sorely missing – especially with respect to down insulation layers. It’s incredibly frustrating to try to compare these in any meaningful way, and it’s clear that the larger manufacturers have zero desire to provide the information needed to do so. The opposite, really: they, even most of the best regarded ones, are far more focused on muddying the waters so you’ll simply buy their product out of frustration. I agree with your notes re marketing vs engineering/performance. You’re at the top of my list for my next orders of down goods.

Very interesting content. It’s hard to compare the warmth of different jackets due to differences in fill weight, fill power, construction, materials, etc that makes it hard to gauge the actual warmth as a consumer.

For example, I’m looking at the Klattermusen Farbaute jacket, which has 170G of 800+ down, and uses box-baffle construction with extra seals on the zippers. Do you think that would be meaningfully warmer (5-10 degrees) than an Arcteryx Thorium AR (130G 750 down + 15% synthetic fill, sewn through baffles)?

Or would it be better to get something with 250G of down (like Rab infinity and similar jackets) with box wall construction to notice a noticeable difference?

Trying to figure out if just the box-wall construction of the Farbaute jacket is already enough to get a significantly warmer jacket, or if fill weight still matters a lot more.

Total fill weight is a very inaccurate metric for comparing warmth because the total area being filled is likely to vary by considerable margins. I wouldn’t even begin to compare anything until I had some relevant volumetric spec that applies throughout. Basically you want to know the calculations used to fill any chamber. Not an amount spread over an unknown area. Calculated loft is one way of expressing it and you’ll see some writing about it here. Check it out.

Thanks Dan, does that then depend solely on the size of the jacket (long/short/wide)? I can understand that the same amount and fill power down in a short jacket will be warmer (for the parts of the body covered) than a long jacket, as the same amount of down is spread more thinly. Or does it also depend on construction/design of the baffles of the jacket?

Asking specifically because rough dimensions of jackets are somewhat available if you ask manufacturers, but more detailed info is hard to find.

Re: my mentioned examples, the two jackets are roughly the same size, although I’m guessing even a ‘roughly’ same size jacket can probably easily differ 20% or more in surface area if you’d actually measure it exactly.

It has to do with dimensions and features. Subtle changes in dimensions between sizes that are considered equivalent, account for large variances in total area insulated. Differences in features like hoods, draft tubes, flaps, insulated pockets, etc can account for large differences in total area insulated in items considered equivalent. Roughly similar dimensions and features will still result in large variances in total area insulated. You want a concrete metric that indicates the general level of insulation in any given section of a garment, regardless of its size, or fill power, or features. Every down garment is filled using this number during manufacturing and every manufacturer should have it in some shape or form. Read the post on “Calculated Loft”.

Regarding “construction/design of the baffles”, this is a separate question really. I’ll try to answer it this way. As described above, you need to be starting with something concrete, but say you have two garments. Both are filled to 2.5″ calculated loft, but one is sewn through and the other has box chambers. The one with box baffles is likely to be considerably warmer than the one without. There are other considerations though. Below a certain point, baffles are not reasonable to sew in and the benefits would be minimal when they are really short. Baffles are labor intensive and increase the cost quite a bit. They add weight…..sometimes you could increase the calculated loft of a sewn through garment by a margin equal to the weight of the baffles and end up a wash. Building the garment with baffles would be more efficient per amount of fill, but adds the weight of the baffles. Building a sewn through garment with an increased amount of calculated loft could make up the difference in insulation and end up at the same weight. This is not a standard rule, but a scenario that can exist.

In summary, there are enough variables to consider when comparing down garments. Using total fill weight is already starting with such an unreasonably large margin of error that once you consider all of the variables, the whole thing is a complete shot in the dark. At least we can start with a concrete metric that means something. Calculated loft won’t tell the whole story, but it will give a stable foundation to assess all the variables from.

Hey Dan 👋

Thank you very much for the great content on your blog. Your stories are really insightful and I learned a lot!

I’m currently especially interested in ultralight down insulation garment. More specifically puffy jackets. I’m comparing various products and ask the manufactures for the metrics you suggest. Namely the loft, baffle spacing and overstuffing. But if I compare these numbers to one of your products, I get confused. And I still feel like I lack some understanding.

In the following I’m trying to compare the Cumulus Primelite Pullover (link below) with the Timmermade SDUL .75 down sweater. First of all, the approx. total and fill weight values are given for different reference sizes. Timmermade for size small and Cumulus size medium. I used the detailed size chart by Cumulus and made up some calculation to get defective downscaled values for size small.

Here are the raw numbers first. I always use the original values with their unit first. Providing the converted numbers in parentheses.

The calculated loft of the SDUL sweater is 0.75 inches (~19mm). The measured loft of the Primelite is 12.5mm (~0.5 inches). Baffle spacing compares 4 inches (~101mm) to 50mm (~1.97inches). Overstuff according to your blog is about 160% for most of your Timmermade products and 108% overstuffing by Cumulus. Fill powers are 1000fp versus 850fp goose down. Fill weight ~1.55oz (~44g) to ~82g (~2.9oz). Total weight ~3.6oz (~102g) to ~6.5oz (~184g).

Both are pullover/sweater style with no hood, a short collar and taper fit. Both use sewn through baffles. The Primelite has an unnecessary short zipper and a chest pocket adding extra weight. The SDUL in contrast has some useful draft cords.

Timmermade uses a lighter 7D nylon shell with 0.49oz/yd^2 (~16.6g/m^2) versus the 7D ripstop nylon with DWR finish by Cumulus that weights 22g/m^2 (~0.65oz/yd^2). Interesting enough both garments have pretty much the exact fill to total weight ratio.

Anyhow, after tons of information about these two garments I have one big question: how does the Timmermade SDUL achieve so much more loft with so much less?

Let’s quickly eliminate an unnecessary confusion factor, the fill power. Assuming both given values refer to the same weight per volume units, the 44g 1000fp of the SDUL equal about 52g of 850fp as Cumulus uses. Still, Timmermade uses about 1/3 less fill.

This significantly less amount of fill material produces over 30% more loft. The chambers are also much larger due to the doubled baffle spacing. So higher loft plus wider chambers should mean much more volume in total. Volume that has to be filled. It makes sense that for this difference in chamber size, the Cumulus gets away with 52% less overstuff as less control is needed. But then again, more overstuffing actually means more fill material in use.

How does that work out all together?

I mean according to your content, you emphasise the importance of metrics like calculated loft in contrast to full weight, just because down garments can vary drastically in their shape, construction and features. But looking at all these information the difference seems huge. Why does the Primelite “produce” so much less loft than the SDUL sweater?

Sure, there are some error margins in the calculation. Starting with the most obvious one, the actual weights. And unfortunately I can’t estimate the impact of comparing measured vs. calculated loft. The cut and shape might differ, though it doesn’t look obvious to me where. I only have a detailed size chart by Cumulus as Timmermade is fully customised as I understand.

But in the end the gap is so enormous, that it actually can’t fit into all these error margins altogether. It feels like I’m missing some key information.

In the end I’m just very keen to learn more about this topic and better understand my gear. Potentially making my own. Thanks for any insights you may provide. 🙏

Best regards,

Thore

Link to the Cumulus Primelite Pullover product:

https://cumulus.equipment/eu_en/men-down-jacket-primelite.html

It seems like you’re kind of confusing yourself with over-analyzing. The basic comparisons being made here aren’t applicable.

“Calculated Loft” and “measured loft” are two entirely different things. Calculated loft is a metric that tells you how much fill, in weight, is in any given area. It’s an objective metric without any variability. Every chamber is filled with this spec and you can very easily know exactly how much weight is in each, using “.75”. Measured loft is a physical measurement of loft height. Since that is highly variable, it is a little unreliable on its own. It’s good info to have, but needs more to back it up. Using these two different metrics together to compare wouldn’t really make any sense.

“Overstuff” doesn’t apply to sewn through construction at all. Overstuff is defined as a percentage of fill above the amount needed to just fill a space. So if you’re filling a box chamber, there is a base volume that is calculated. You then can use that volume to find the amount of down you need, in weight, to exactly fill this volume. An overstuff is applied above this to achieve a density that will result in the fill control you need. Sewn through construction has no base volume. It is two dimensional, so whatever fill you put in is technically all overstuff. The term just doesn’t really apply. Using those 160% and 108% figures here wouldn’t apply at all. I’m not sure what the 108% spec would be referring to, but on the Timmermade side, 160% isn’t applicable in any way to our sewn through garments.

Fill weight and total weight can’t really tell you too much in terms of insulation, regardless of matching up features. Patterns are different, so the total area being insulated is different. The 1.44oz of total fill figure compared to the 2.9oz of total fill means absolutely nothing. Not even a ball park, general idea regarding warmth and loft. It’s like taking 1.5 fluid oz of water and 2.9 floz of water and pouring them into containers with unknown volumes and assuming what the water depth will be. The containers are different sizes, that we don’t know, so we simply cannot make any assumptions at all.

It would be accurate to say the SDUL is achieving more loft and warmth for less weight, but certainly not by these values, and not having anything to do with this line of reasoning. Higher fill power fills more space with less fill weight and wider chamber spacing allows more loft with fewer cold spots. Beyond that, efficient design limits more cold spots. Proper sizing goes a long ways towards preserving loft and warmth and can also go a long ways towards degrading loft and warmth if sized snug.

Thank your very much for your quick answer! Your explanation helped me a lot. So probably I’ll ask again for the calculated loft to get a better idea. But I’d probably favour larger chambers and less features. There are just no real alternatives over here in Europe.

Anyhow. Thank you very much!

Looking forward to new content on your blog!

✌️

I would be curious to hear what reply you get back. To be clear, “calculated loft” is just my term for it and that isn’t really a standardized thing, that I know of. If you ask manufacturers for this, they may not recognize what you are asking for. They will have to have the spec somewhere, but might have a different term for it. To explain it, you’d want to clarify that you’re asking for the volumetric formula used to fill chambers. If you end up with a formula and need help sorting it out, reply back here and I’ll try to help.